Case Study:

AB InBev

Improving quality, efficiency, and reducing costs across AB InBev’s production lines.

AB InBev Case Study: Optimizing Production Efficiency

🏭 Operational Challenge

ABI previously relied on manual crate checks and unreliable in-line sensors, which fell short of the accuracy needed by QA and accounting teams. Additionally, as ABI transitions from crate-count to bottle-count reporting, their previous crate counters offer no support for this shift.

☑️ Applicable Solutions

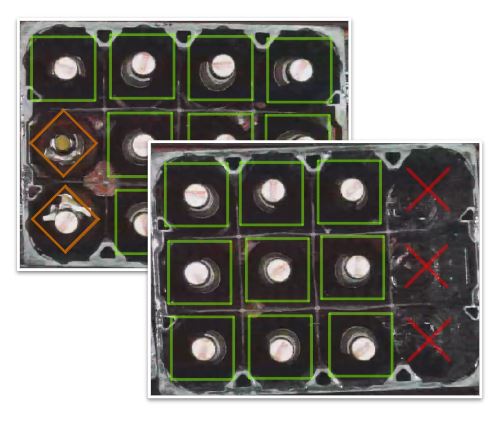

- ☑️ Vision Suite: Crate Inspector

- ☑️ Vision Suite: Closed Loop Rejection

- ☑️ Operations Suite: Shift Reports

- ☑️ Operations Suite: Operator Logbook

- ☑️ Predictive Analytics: Thermal & Condition Monitoring

💰 Business Impact

- 💰 Eliminates manual QC bottlenecks

- 💰 Enables rapid brand changeovers

- 💰 Enhances compliance and traceability

- 💰 Optimizes maintenance scheduling

📊 Quantifiable Metrics

- 📊 99.99% inspection accuracy at 7,200 crates/hour

- 📊 99.99% rejection accuracy on conveyors at 1m/s

- 📊 Total crates scanned: ~750,000 (monthly / line)

- 📊 Total bottles scanned: ~8.8 million (monthly / line)

- 📊 Total bottles scanned: ~2.1 billion (annually, 30 lines)

ROI Highlights

7,200 Crates / Hour

Handles single or dual conveyors at up to 1 m/s.

99.99% Inspection Accuracy

Detects bottle presence, fill level, and crate defects in real time.

99.99% Rejection Accuracy

Rejects crates not meeting quality standards. No sensors required.

83,000 Crates Rejected

Crates automatically rejected per year on average (per line).

$415k Avoided Loss

Estimated savings (per line) from accurate rejection and inspection.

$12.5M Avoided Loss

Annual savings from automated inspection (across 30 lines).